Internet Explorer is not supported

Sorry, please use another browser such as Google Chrome or MozillaFirefox

What would you like to explore first?

Why go digital?

Designing custom products by hand is a true craftsmanship, requiring years of expertise to achieve the perfect custom fit. With 3Shape solutions, including 3Shape Advance, achieve this fit effortlessly by capturing every detail from the ear in your modeling design through a tailored and automated workflow covering scan, design, and print.

Reduce total cost per unit

Decrease labour costs in all steps while minimizing overall use of materials and excess materials in 3D printing. Easily remake broken or lost units with a design recall feature.

Improve control of your current work

Mirror your current processes digitally to bring repeatability and consistency to your modeling. Improve retention rates and decrease remakes by introducing AI-powered automation - ensuring the perfect fit the first time.

Build a resilient business

Make your business more agile and scalable by enabling remote design work and easy onboarding into the software. 3Shape Advance allows you to effortlessly adapt your production to fluctuating order volumes.

Onboard modelers more efficiently

Onboard inexperienced modelers and quickly see them handle ever larger volumes and more complex products within weeks. Support modeler development and motivation through insights over time.

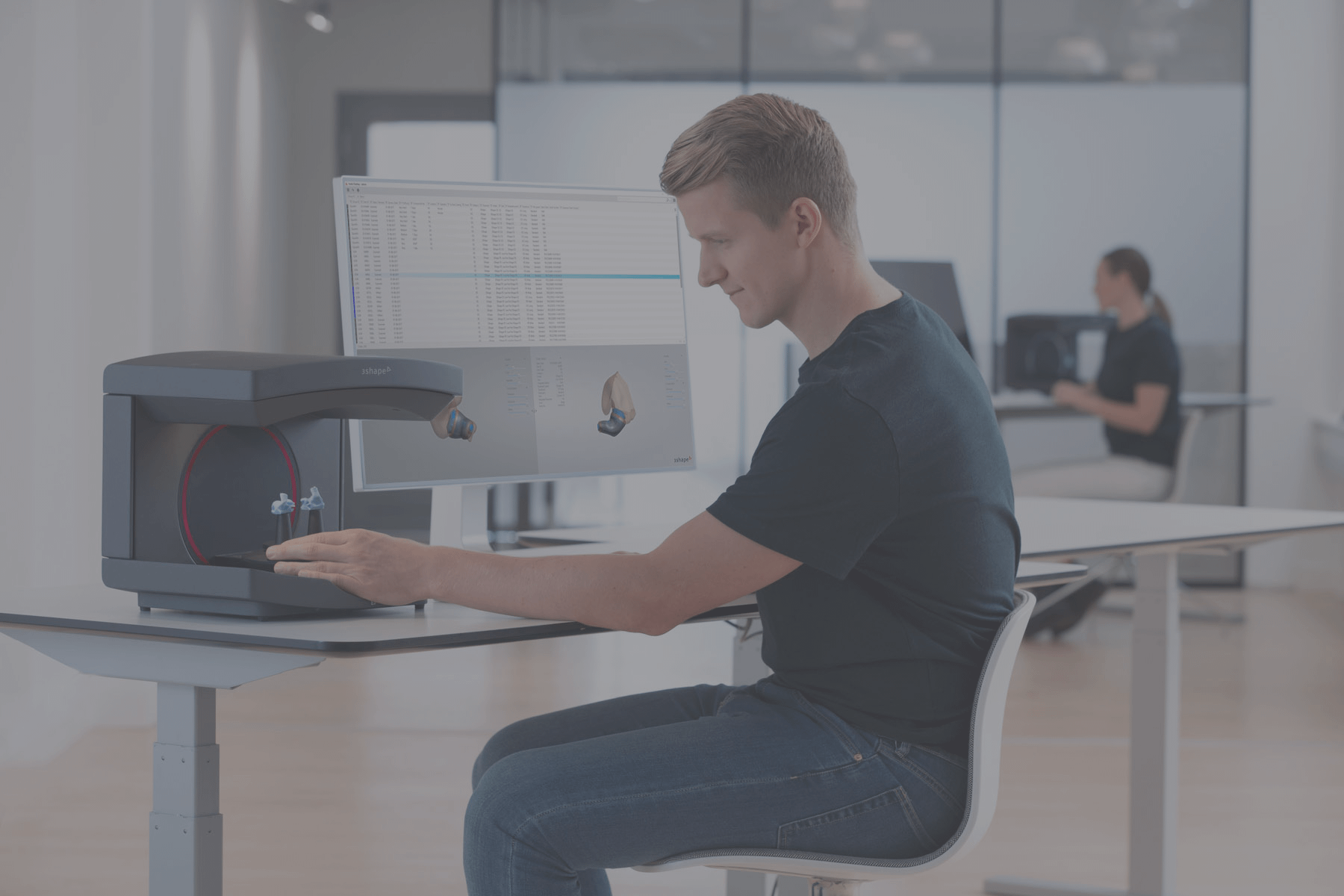

3Shape Audio digital workflow

Digital technologies have truly revolutionized how custom audio devices are made today. Wherever you are on your digital journey, our solutions and support enable you to work faster, more accurately and cost-effectively.

Scan

When you work in a digital workflow, you scan ear impressions or receive scans digitally. All 3Shape Audio scanners are ISO-documented accurate, ultra-fast, and backed by our twenty years of experience in creating ground-breaking solutions for custom audio devices.

Design

3Shape’s solutions will improve the accuracy, efficiency and repeatability of your hearing aid, noise protection, communications and in-ear music device designs. 3Shape Advance automates the entire design process, allowing you to send the product straight from scan to print.

Manufacture

When you design with 3Shape software, your designs are compatible with most 3D printers. 3Shape Audio solutions enable you to manage, automate, and streamline your production workflows.

Over to you

Automation is creating new possibilities for custom audio devices, making processes faster and more efficient than ever before. Enhance customer satisfaction and improve business effectiveness by reducing manual tasks and streamlining your workflow. Browse our custom design software or explore our automated design solutions to discover how you can optimize your processes from start to finish.

“The service from 3Shape is incredible, and the software is working remarkably. My manufacturing is becoming so streamlined with such accurate builds, it has elevated my whole game.”

Simon Fisk, Plunge Audio, Canada

Contact 3Shape Audio regarding availability of products in your region or country.